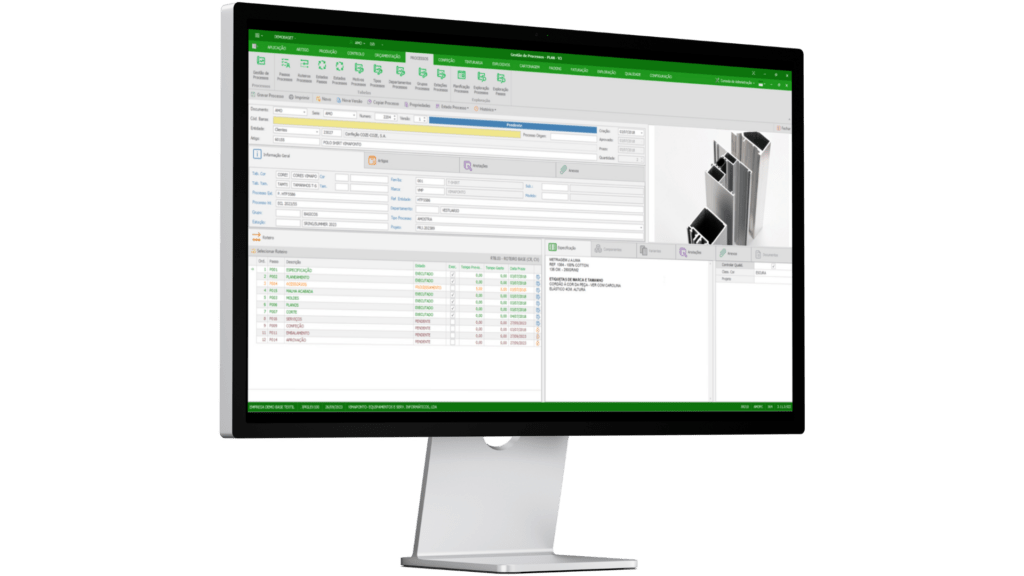

Metalworking Industry

As empresas do setor da metalomecânica são constantemente confrontadas com a necessidade de otimizar processos de modo a aumentar a competitividade e a rentabilidade. O VMP Plan, integrado no ERP v10 da Cegid, é uma solução de gestão completa que abrange toda a organização, desde a produção até à gestão de topo.

VMP Plan promotes comprehensive management of the production cycle in a fully integrated way, eliminating the most time-consuming and lower value-added tasks. It encompasses all production processes in the metalworking industry, such as:

– Product Development

– Needs Calculation

– Quality Control

– Etc.

This solution results from over 35 years of experience in various sectors, incorporating a set of standard processes coupled with flexibility that allows adapting the VMP Plan to the specific needs of each organization.

main features

Product Development

– Management and control of sample execution

– No need to create an article

– Customers or potential customers

– Various execution and control workflows

– Unlimited and user-configurable operations/steps

– Cost and time recording per operation

– Automatic email notification upon operation completion

– Sample documentation repository

Budgeting

- Creation of budgets and price lists

- Budget creation without the need to create articles

- Unlimited templates for Excel calculations

- Communication between the database and Excel

- Budgets with version tracking and approval control

- Commission grids by seller, brand, customer, etc.

- Definition of commissions for automatic calculation

- Prices based on dimensions (colors, sizes, etc.) and ranges

- Simulation for production quantities

- Attribute transfer to the article sheet

Assisted Article Creation

– Guided article creation

– Automatic attribute suggestion

– Graphic exploration of the composition of the article

– Technical sheet with unlimited operations and levels

– Combination of technical sheets

– Clear definition of the manufacturing process

– Production alternatives

– Attached images and files

Manufacturing Orders

- Order placement for manufacturing in various modes (automatic, grouped, ungrouped)

- Manufacturing orders without a specific order

- Utilization of ongoing productions and/or stock

- Verification of fulfilled orders

- Calculation of customer tolerance and/or article waste

- Printing with various formats and article images

Needs Calculation

– Requirements by manufacturing orders or orders

– Calculation with various parameters: current and minimum stock, supplier requisitions, operations, and warehouses

– Automatic component requisition

– Usual supplier suggestion

– Material reservation for manufacturing order

Graphic Planning

- Planning view in Gantt chart or grid

- Internal or subcontracted planning

- Fitting suggestion by delivery date or execution time

- Planning alteration through drag & drop

- Load analysis with excess alert

- Industrial calendar with exception possibilities

- Automatic planning using various criteria:

- Customer delivery deadlines

- Execution times at each workstation

- Capacity factors and schedules

- Exceptions for workable hours and capacity

- Among others

Movement

– Permanent inventory

– Material preparation

– Automatic issuance of certified goods tracking document

– Movement executed by operators

– Visibility and recording by subcontractors

– Material return

Quality Control

– Flexibility in configuring quality tests

– Segmentation by families, brands, etc.

– Definition of test collection moments

– Parameterization and customization of factors that approve or reject tests

Packing List and Picking

– Pre-Packing: Automatic and/or manual distribution by packaging type, destinations, and dimensions

– Packing defined by the operator

– Various packings per order

– Automatic label creation

– Customization of packing and labels per customer

– Shipment from picking

– Calculation of volume and weight

Information Exploration

– Production status analysis

– Cost analysis

– Product traceability

– Article statement and inventory by manufacturing order

– Identification of components consumed throughout the production process

– Custom dashboards

– Production status monitors