Textile and Clothing Industry

As empresas do setor ITV (Indústria Têxtil e Vestuário) são constantemente confrontadas com a necessidade de otimizar processos de modo a aumentar a competitividade e a rentabilidade. O VMP Plan, integrado no ERP v10 da Cegid, é uma solução de gestão completa que abrange toda a organização, desde a produção até à gestão de topo.

The VMP Plan promotes the entire management of the production cycle in a fully integrated way, eliminating the most time-consuming and low-value-added tasks. It encompasses all production processes in the textile sector, such as:

– Spinning

– Weaving/Knitting

– Dyeing/Finishing

– Textile Printing

– Cutting/Confection

– Subcontracting

– Agents

– Packing

– Dispatch of the final product

This solution is the result of more than 35 years of experience in the textile sector, having been incorporated a set of standard processes, combined with a flexibility that allows you to adapt the VMP Plan to specific needs of each organization.

main features

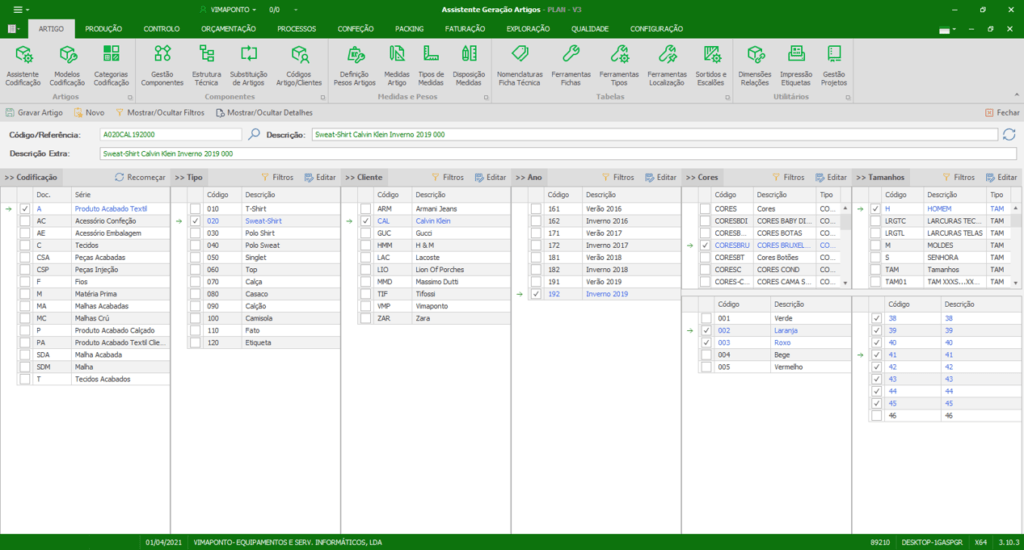

Assisted Article Creation

– Guided article creation

– No need to enter codes

– Automatic attribute suggestion

– Customized per customer

Product Development

- Management and control of sample execution

- Digitization of all sample information exchange and documentation

- No need to create an article

- Clients or potential clients

- Multiple execution and control scripts

- Unlimited and user-configurable operations/steps

- Cost and time recording per operation

- Automatic email notification upon operation execution

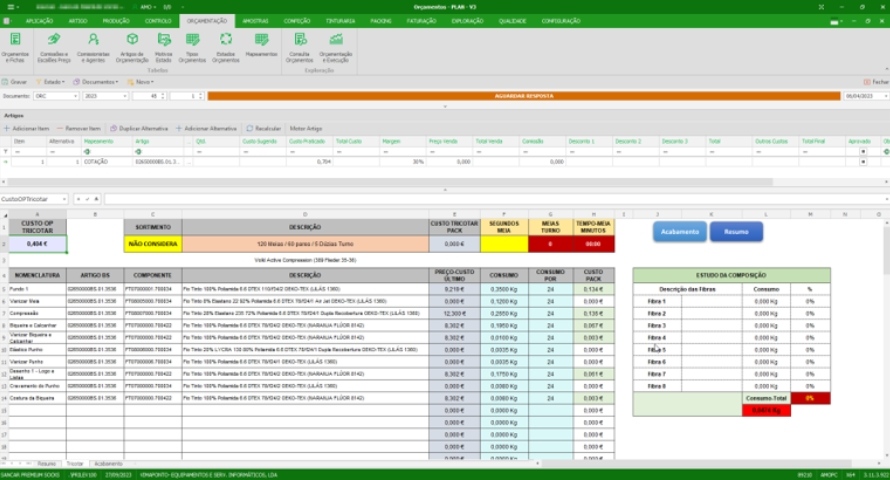

Budgeting

- Creation of budgets and price lists

- Budget creation without the need to create articles

- Unlimited templates for Excel calculations

- Communication between the database and Excel

- Budgets with version tracking and approval control

- Commission grids by seller, brand, customer, etc.

- Definition of commissions for automatic calculation

- Prices based on dimensions (colors, sizes, etc.) and ranges

- Simulation for production quantities

- Attribute transfer to the article sheet

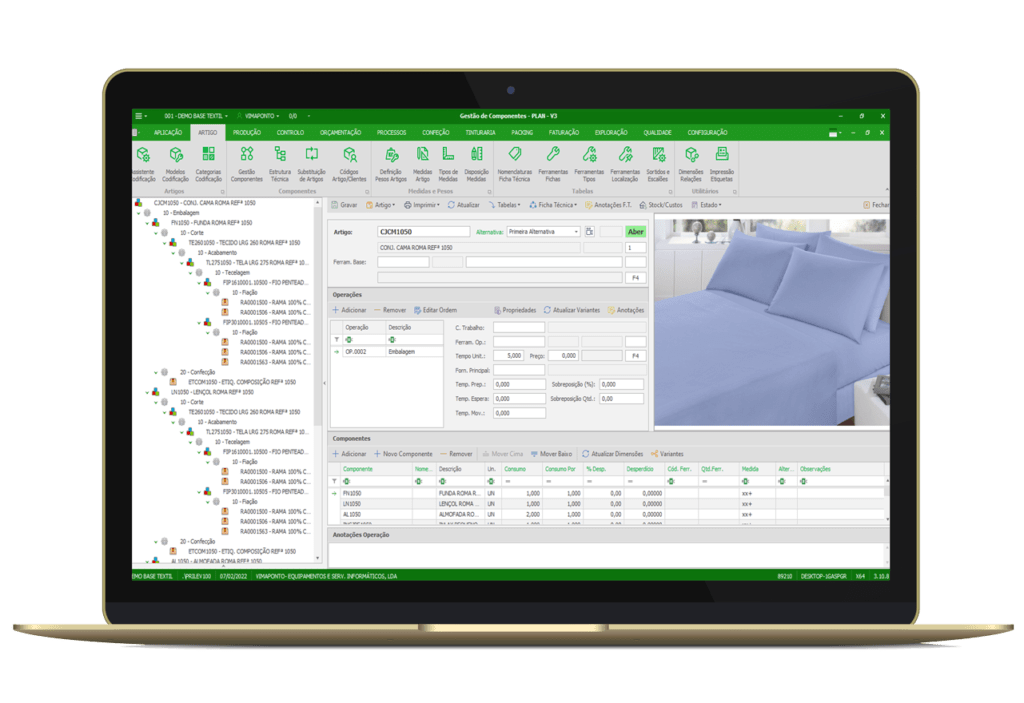

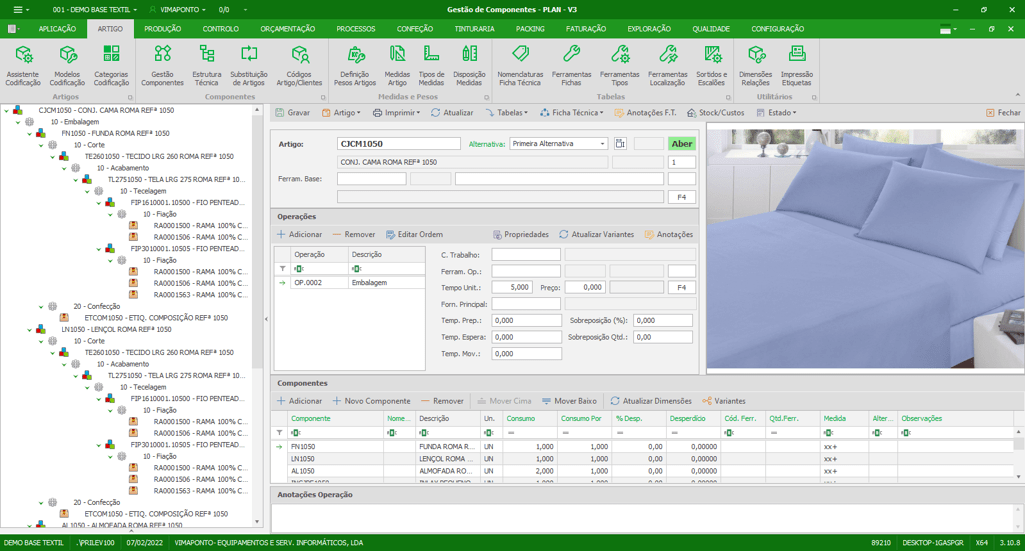

Technical Sheet / Component Management

– Scanning of all product information – supports attachments in various formats (Word, Excel, PDF, PNG, JPG, etc.)

– Automatic expansion of components, consumption and waste by dimension (color, size, etc.)

– Simultaneous change for the entire dimension

– Graphic exploration of the composition of the article

– Variable and unlimited operations

– Copy of Technical Sheets

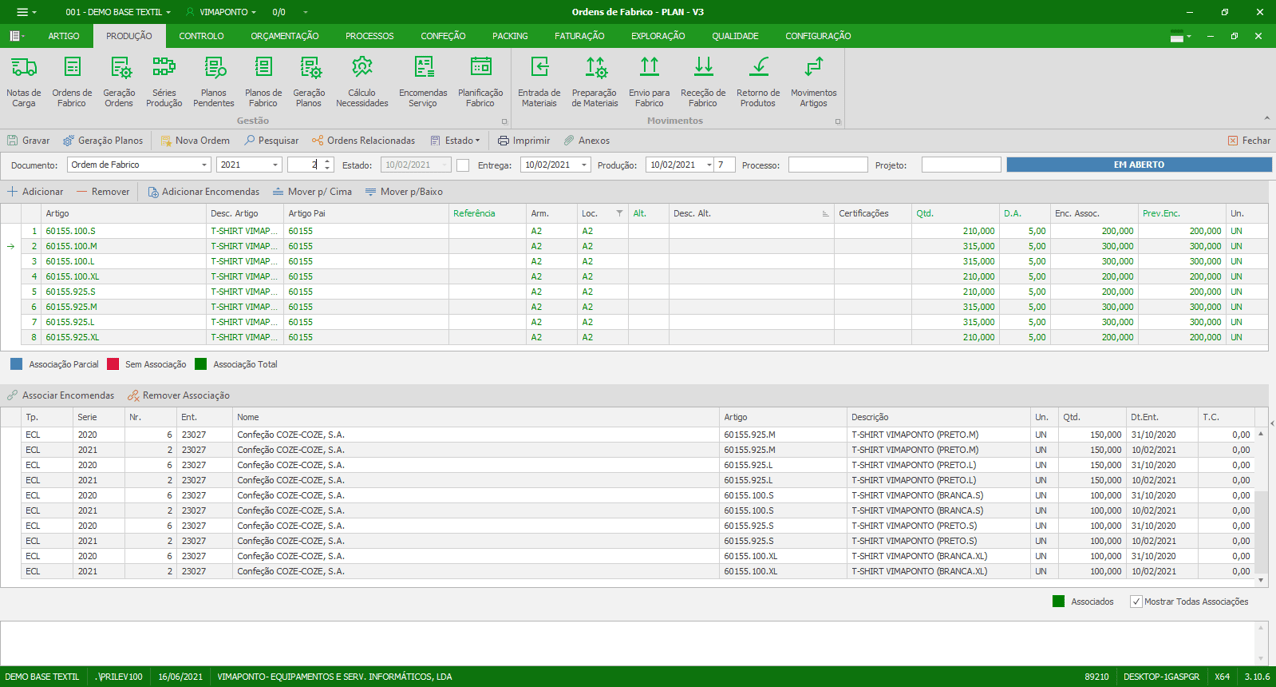

Manufacturing Order

- Order placement for manufacturing in various modes (automatic, grouped, ungrouped)

- Manufacturing orders without a specific order

- Utilization of ongoing productions and/or stock

- Verification of fulfilled orders

- Calculation of customer tolerance and/or article waste

- Printing with various formats and article images

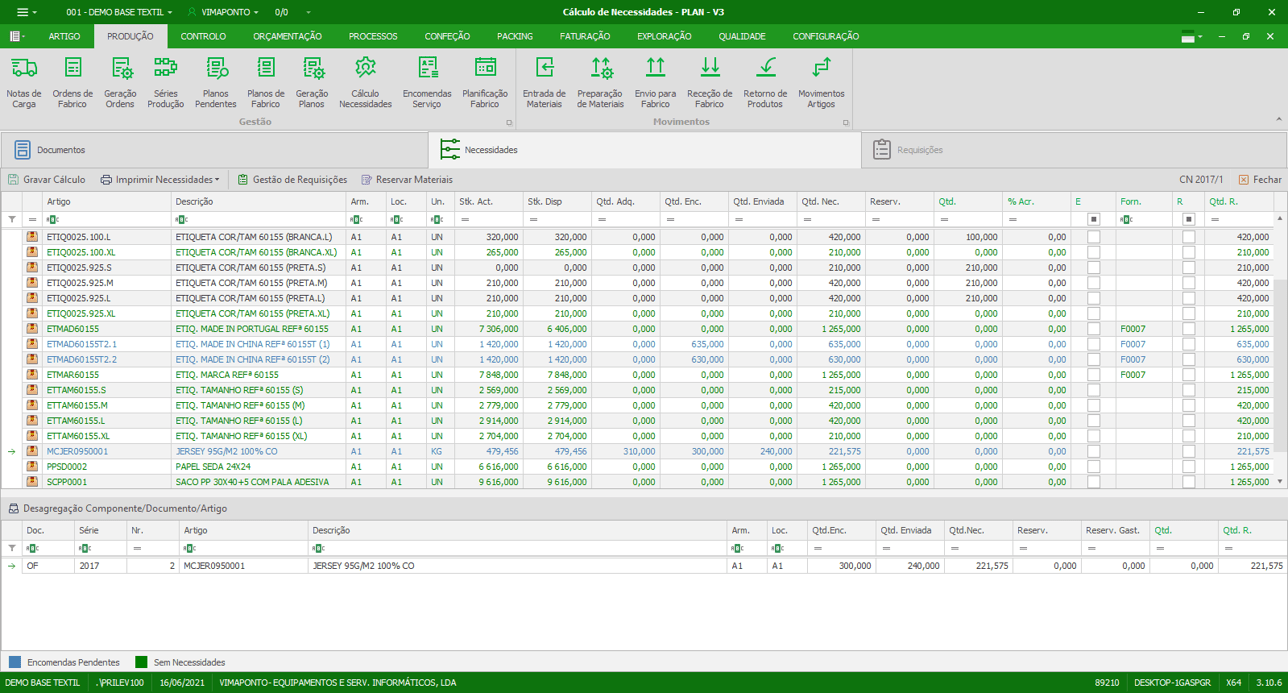

Needs Calculation

- Requirements for multiple manufacturing orders

- Calculation with various parameters: current and minimum stock, supplier requisitions, operations, and warehouses

- Automatic creation of component requisitions

- Suggestion of regular supplier and last purchase price

- Reservation of materials for manufacturing order

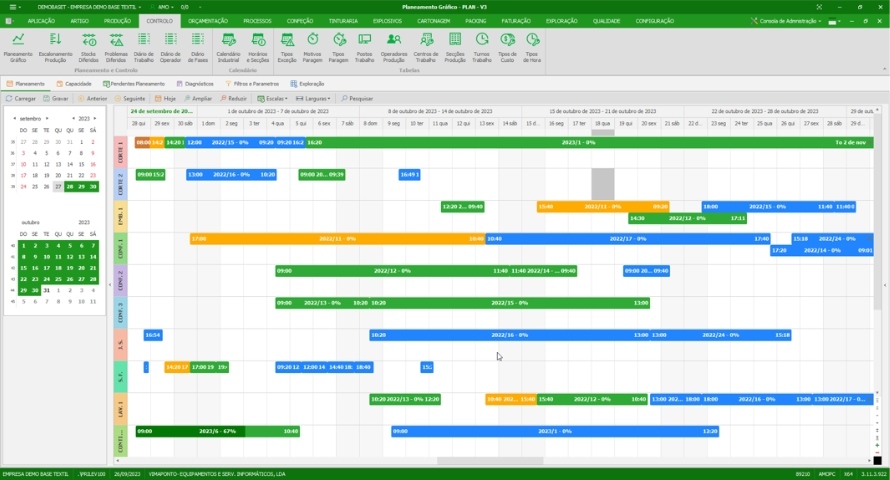

Graphic Planning

- Planning view in Gantt chart or grid

- Internal or subcontracted planning

- Fitting suggestion by delivery date or execution time

- Planning alteration through drag & drop

- Load analysis with excess alert

- Industrial calendar with exception possibilities

- Automatic planning using various criteria:

- Customer delivery deadlines

- Execution times at each workstation

- Capacity factors and schedules

- Exceptions for workable hours and capacity

- Among others

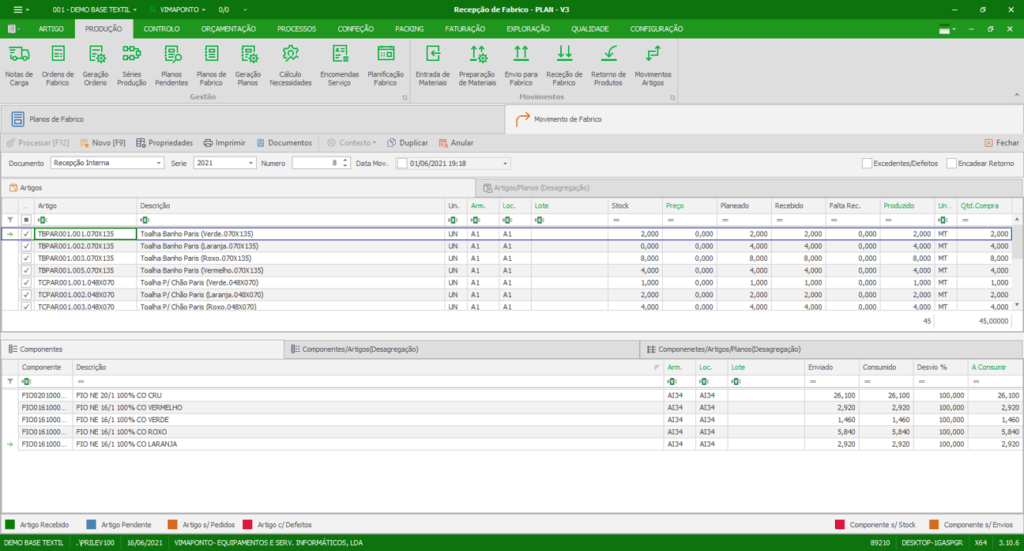

Manufacturing Movement

– Preparation of materials for manufacturing

– Shipping and return of components for internal or external manufacturing

– Automatic creation of certified merchandise tracking documents

– Reception of produced goods

– Online representation in stocks

– Inputs / Outputs on mobile devices

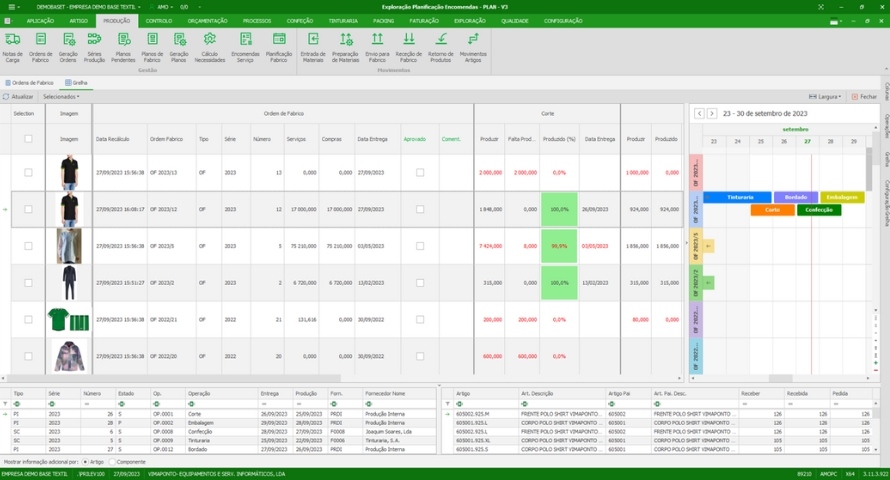

Production Monitoring

– Production status dashboards

– Real-time production monitoring

– Quantities and percentage completed and outstanding by sector

– Materials sent and consumed

– Product traceability

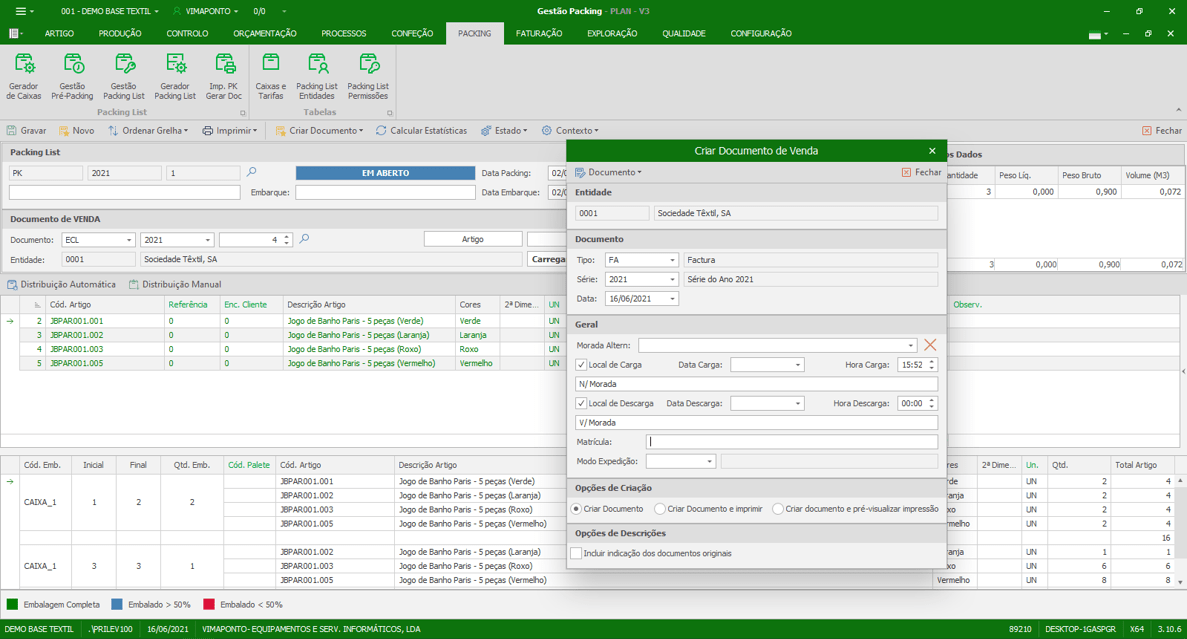

Shipping / Packing Lists / Labeling

– Automatic and/or manual calculation by type of packaging, destinations (stores) and dimensions (colors, sizes, etc.)

– Various packings per order

– Automatic label creation

– Customization of labels and packing by customer

– Packing executed in terminal

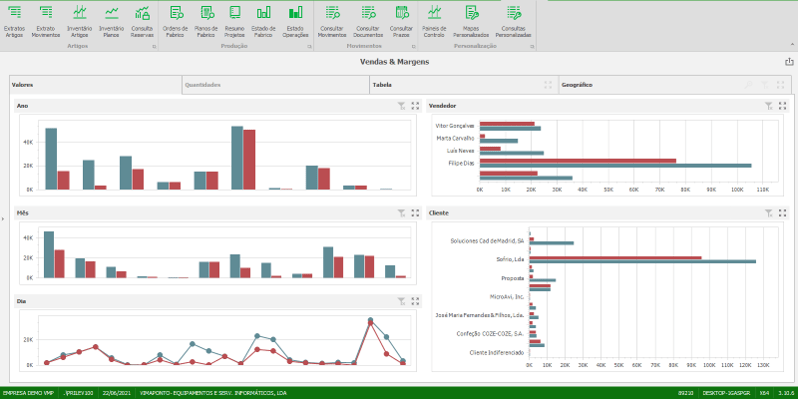

Information Exploration

– Production status analysis

– Cost analysis

– Product traceability

– Article statement and inventory by manufacturing order

– Identification of components consumed throughout the production process

– Custom dashboards

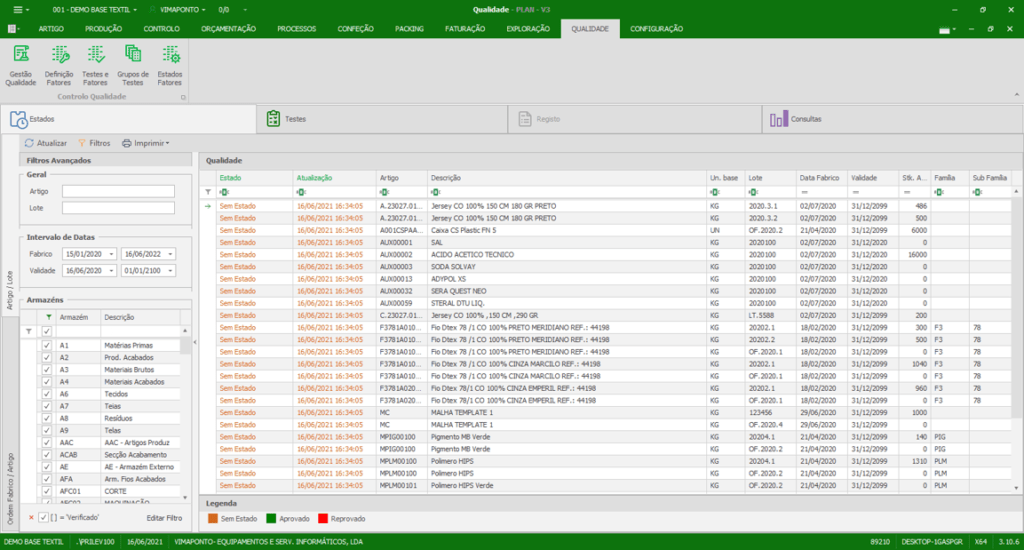

Quality Control

– Flexibility in configuring quality tests

– Segmentation of tests to be registered by families, brands, etc.

– Definition of the collection times for each test or test group, under customizable conditions

– Parameterization and customization of factors that approve or reject each test

Collection of Information in Manufacturing Shop Floor

– Recording information through touch interface on fixed or mobile devices

– Production line segmentation

– Recording of produced quantities

– Recording of production times and stops

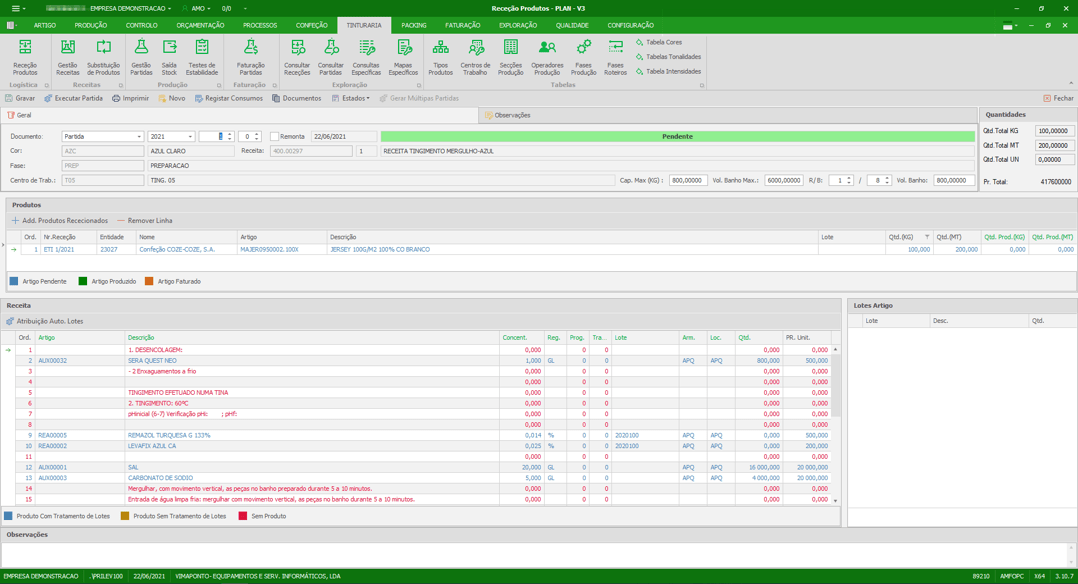

Dyeing Management

– Recipe creation and management

– Integration of recipes with “jets” of dyeing

– Receipt of materials

– Item management (one or several manufacturing orders)

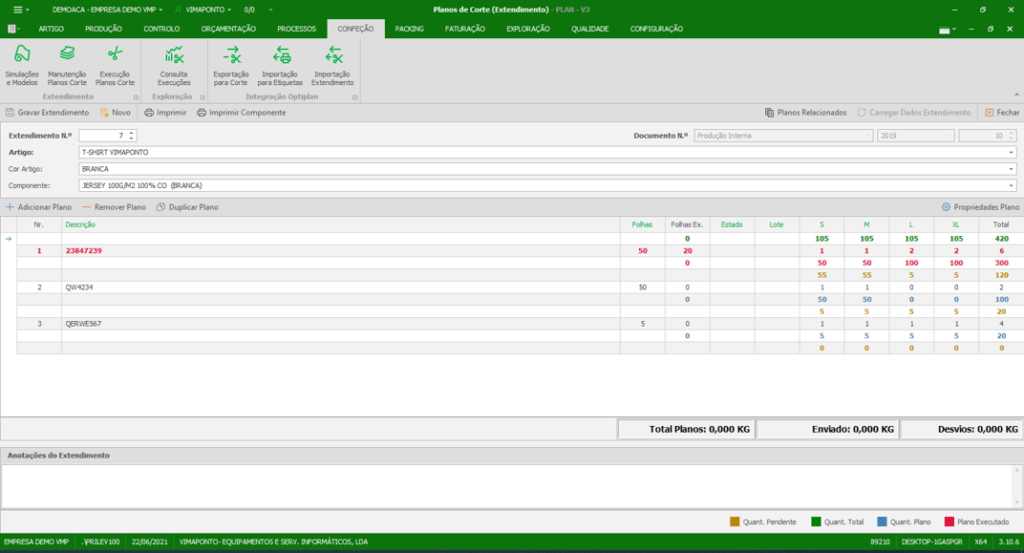

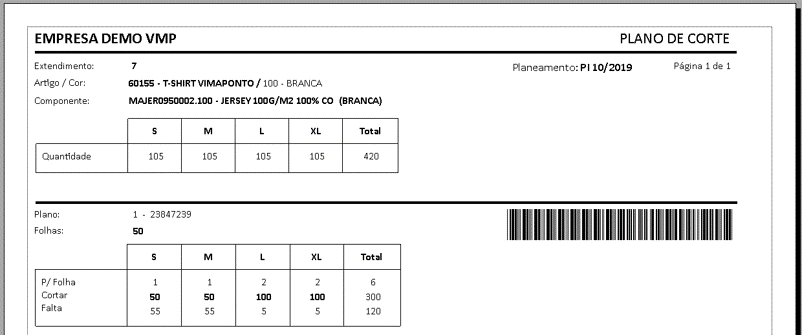

Cutting Plan Management

– Definition of extension plans for cutting

– Unlimited cutting plans per article/color/component

– Execution via barcode reading

– Integration with Optiplan, ICF, Audaces