MANUFACTURING MANAGEMENT AND CONTROL SOLUTION

SOFTWARE FOR THE TEXTILE AND APPAREL INDUSTRY

Automate Processes in the Textile Industry with VMP Plan

Companies in the Textile and Apparel Industry are constantly faced with the need to optimize processes to enhance competitiveness and profitability. VMP Plan, integrated into Cegid's ERP v10, is a comprehensive vertical management solution that encompasses the entire organization, from production to top-level management.

VMP Plan offers a comprehensive solution for textile companies looking to optimize their production. With features such as real-time monitoring and supply chain management, the software enables strict control of processes and supports improvements in operational efficiency. It covers all production processes in the textile sector, including:

– Spinning

– Weaving/Knitting

– Dyeing/Finishing

– Textile Printing

– Cutting/Confection

– Subcontracting

– Agents

– Packing

– Dispatch of the final product

This solution is the result of more than 35 years of experience in the textile sector, having been incorporated a set of standard processes, combined with a flexibility that allows you to adapt the VMP Plan to specific needs of each organization.

main features

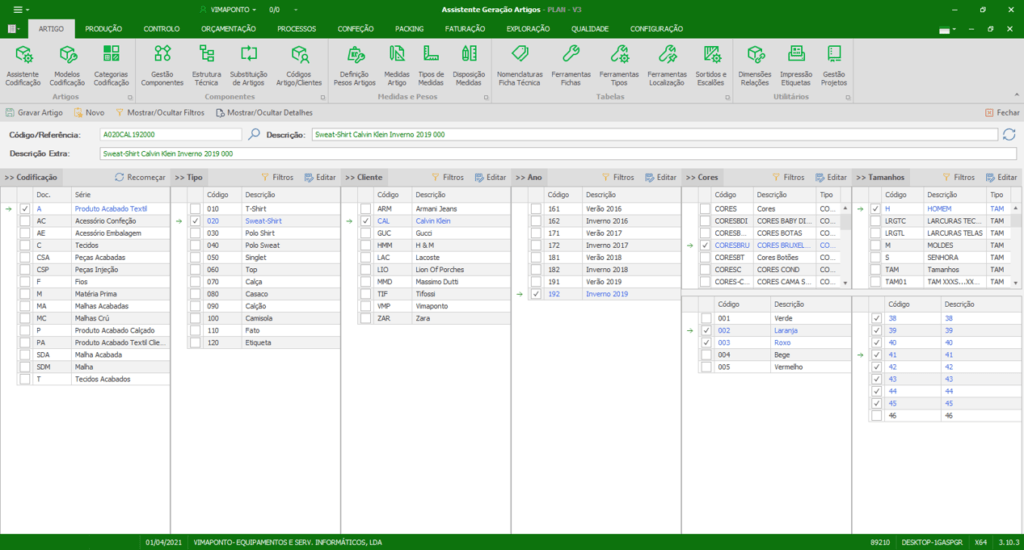

Assisted Article Creation

– Guided article creation

– No need to enter codes

– Automatic attribute suggestion

– Customized per customer

Product Development

- Management and control of sample execution

- Digitization of all sample information exchange and documentation

- No need to create an article

- Clients or potential clients

- Multiple execution and control scripts

- Unlimited and user-configurable operations/steps

- Cost and time recording per operation

- Automatic email notification upon operation execution

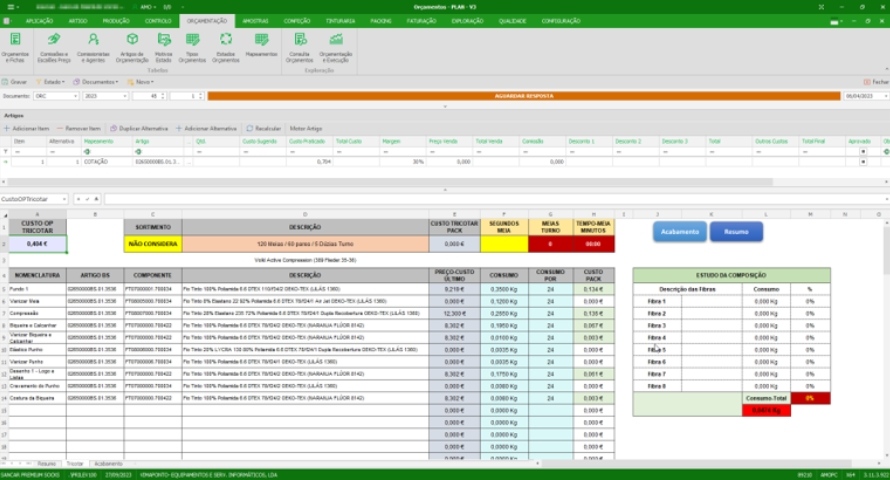

Budgeting

- Creation of budgets and price lists

- Budget creation without the need to create articles

- Unlimited templates for Excel calculations

- Communication between the database and Excel

- Budgets with version tracking and approval control

- Commission grids by seller, brand, customer, etc.

- Definition of commissions for automatic calculation

- Prices based on dimensions (colors, sizes, etc.) and ranges

- Simulation for production quantities

- Attribute transfer to the article sheet

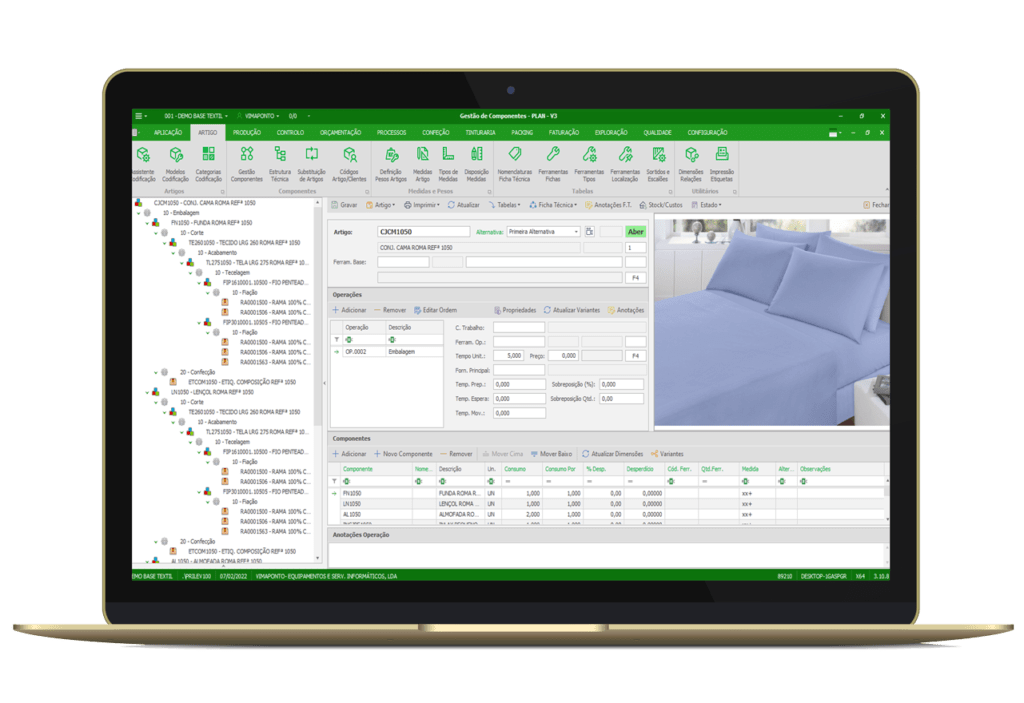

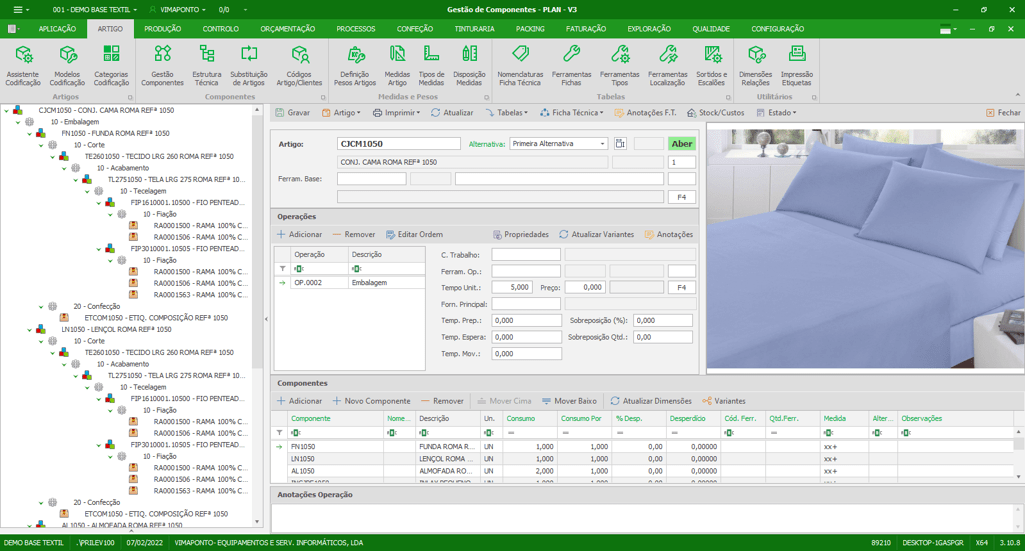

Technical Sheet / Component Management

– Scanning of all product information – supports attachments in various formats (Word, Excel, PDF, PNG, JPG, etc.)

– Automatic expansion of components, consumption and waste by dimension (color, size, etc.)

– Simultaneous change for the entire dimension

– Graphic exploration of the composition of the article

– Variable and unlimited operations

– Copy of Technical Sheets

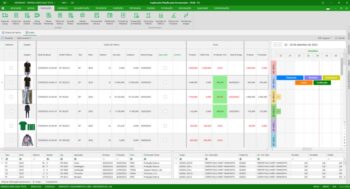

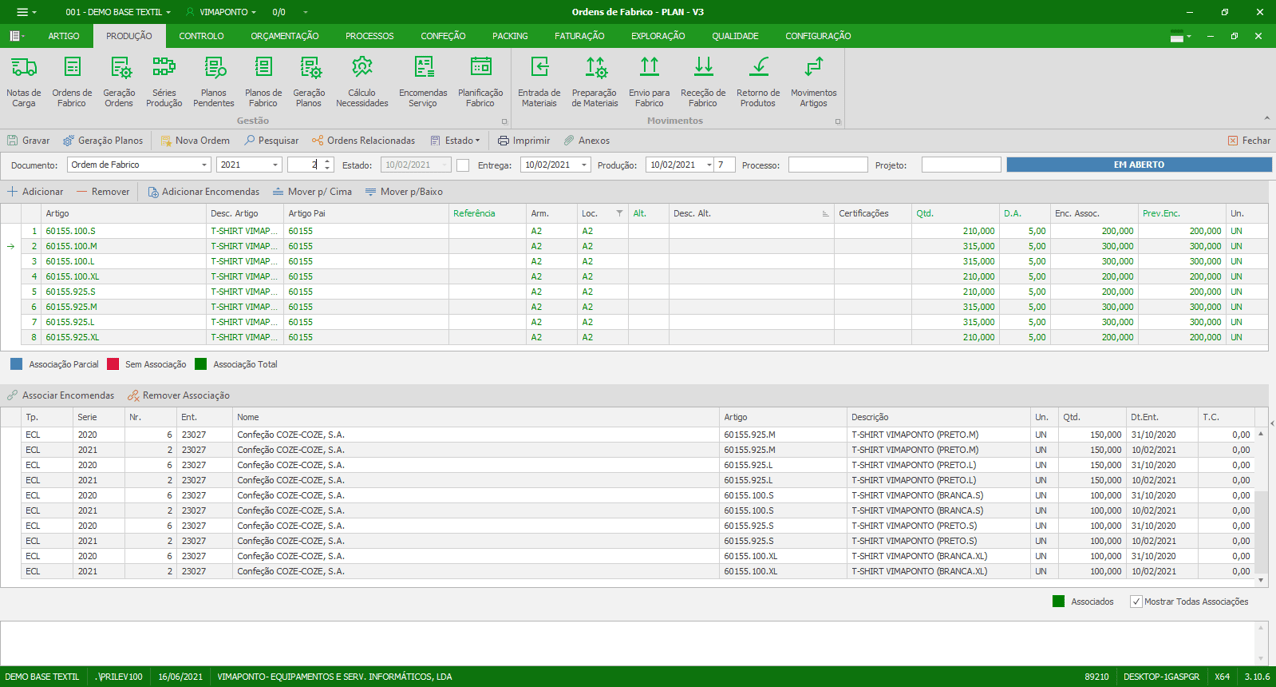

Manufacturing Order

- Order placement for manufacturing in various modes (automatic, grouped, ungrouped)

- Manufacturing orders without a specific order

- Utilization of ongoing productions and/or stock

- Verification of fulfilled orders

- Calculation of customer tolerance and/or article waste

- Printing with various formats and article images

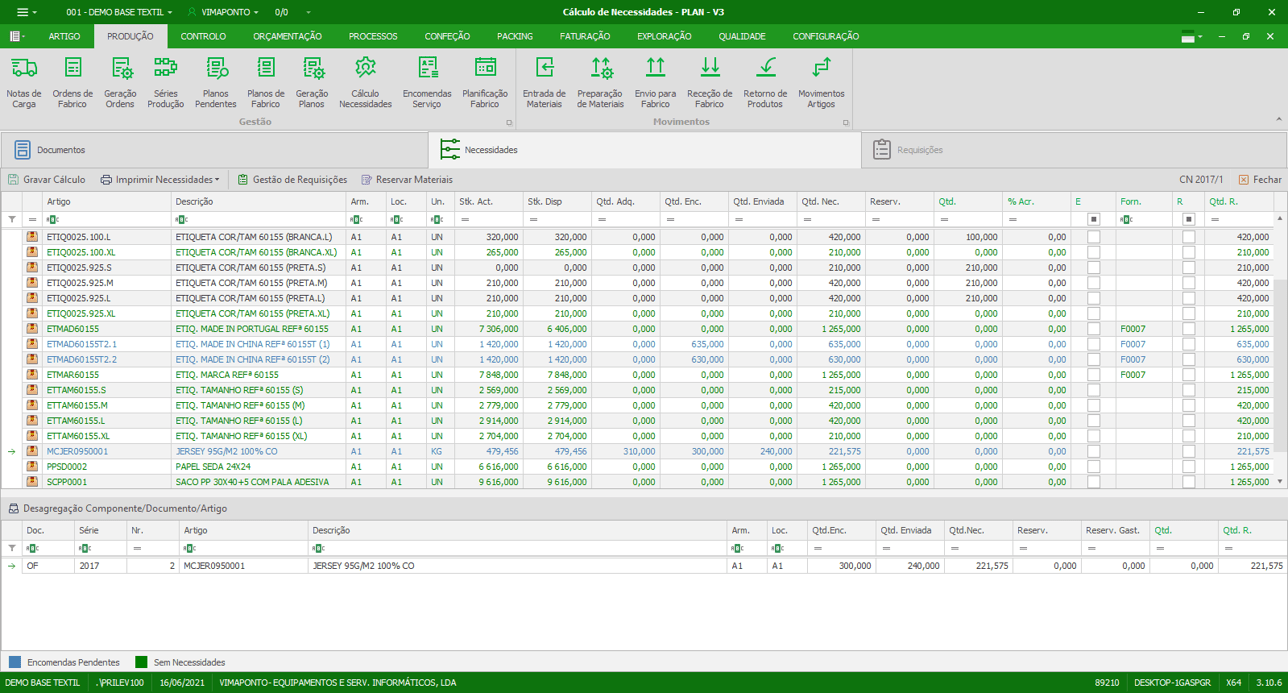

Needs Calculation

- Requirements for multiple manufacturing orders

- Calculation with various parameters: current and minimum stock, supplier requisitions, operations, and warehouses

- Automatic creation of component requisitions

- Suggestion of regular supplier and last purchase price

- Reservation of materials for manufacturing order

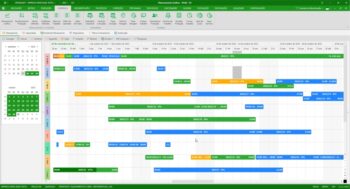

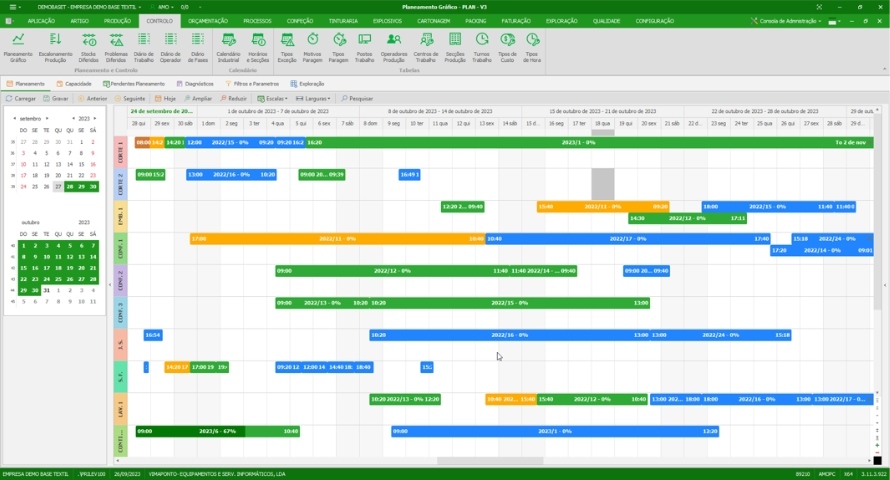

Graphic Planning

- Planning view in Gantt chart or grid

- Internal or subcontracted planning

- Fitting suggestion by delivery date or execution time

- Planning alteration through drag & drop

- Load analysis with excess alert

- Industrial calendar with exception possibilities

- Automatic planning using various criteria:

- Customer delivery deadlines

- Execution times at each workstation

- Capacity factors and schedules

- Exceptions for workable hours and capacity

- Among others

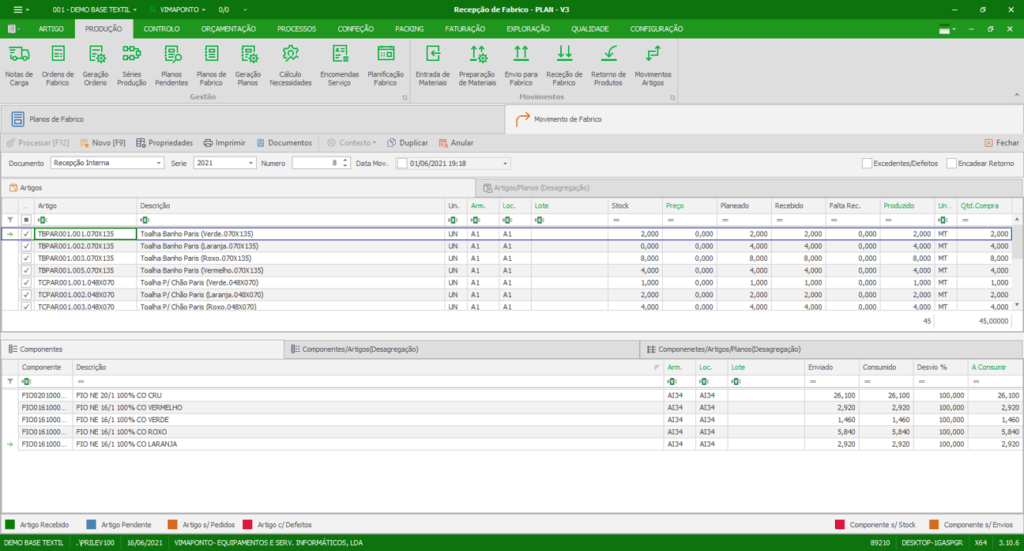

Manufacturing Movement

– Preparation of materials for manufacturing

– Shipping and return of components for internal or external manufacturing

– Automatic creation of certified merchandise tracking documents

– Reception of produced goods

– Online representation in stocks

– Inputs / Outputs on mobile devices

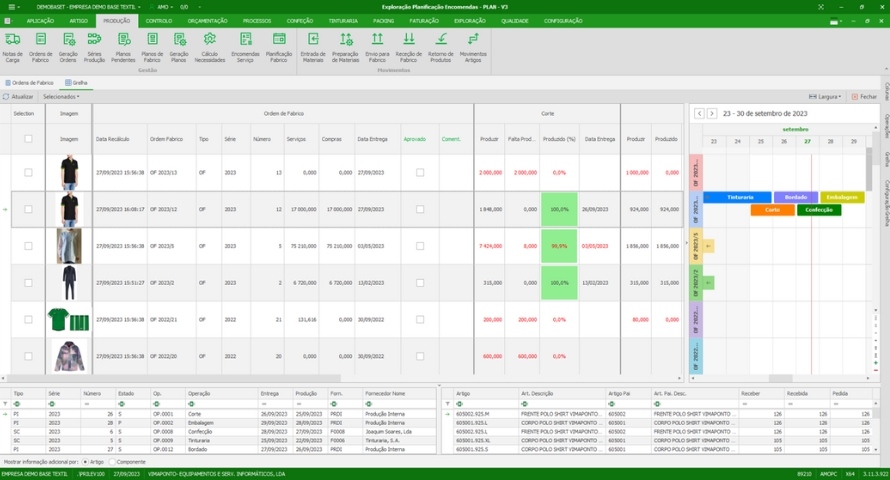

Production Monitoring

– Production status dashboards

– Real-time production monitoring

– Quantities and percentage completed and outstanding by sector

– Materials sent and consumed

– Product traceability

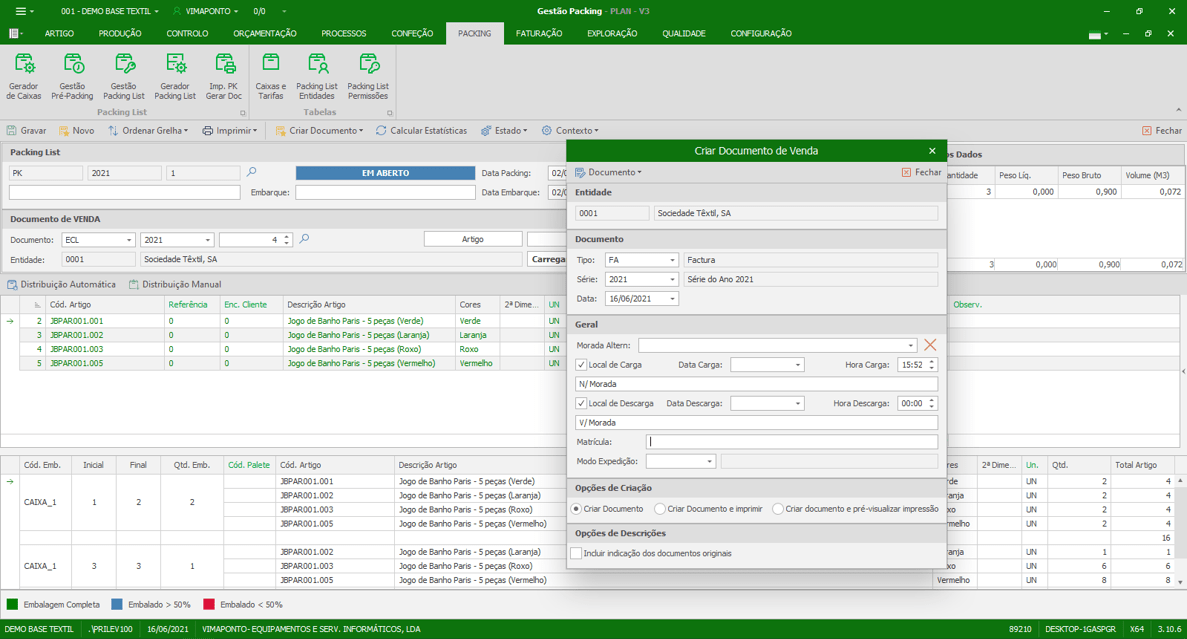

Shipping / Packing Lists / Labeling

– Automatic and/or manual calculation by type of packaging, destinations (stores) and dimensions (colors, sizes, etc.)

– Various packings per order

– Automatic label creation

– Customization of labels and packing by customer

– Packing executed in terminal

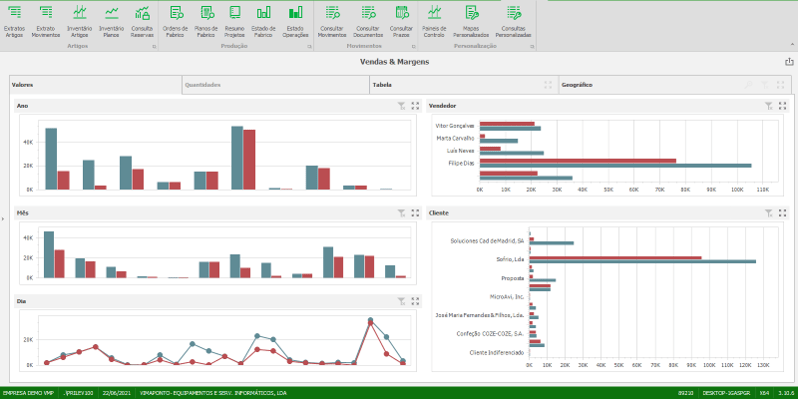

Information Exploration

– Production status analysis

– Cost analysis

– Product traceability

– Article statement and inventory by manufacturing order

– Identification of components consumed throughout the production process

– Custom dashboards

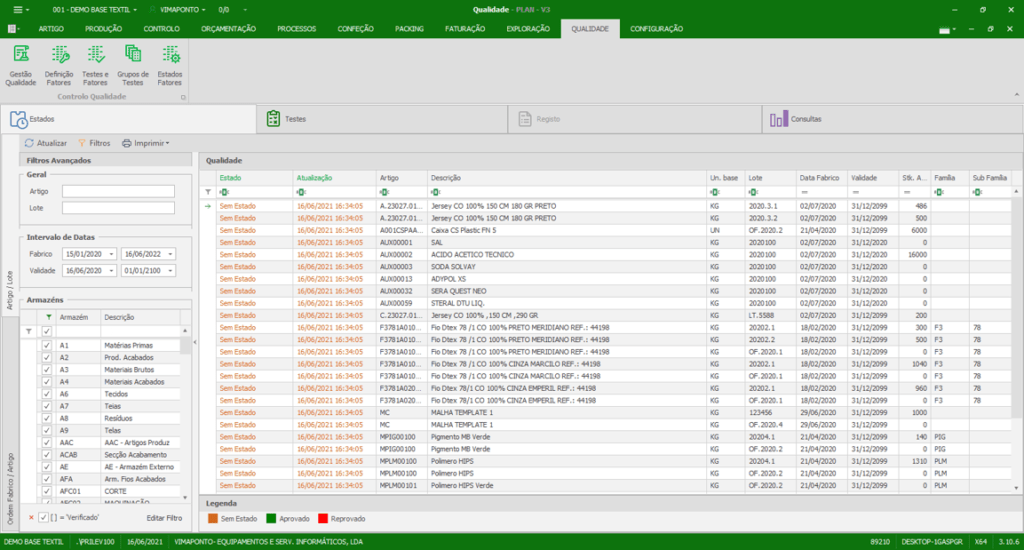

Quality Control

– Flexibility in configuring quality tests

– Segmentation of tests to be registered by families, brands, etc.

– Definition of the collection times for each test or test group, under customizable conditions

– Parameterization and customization of factors that approve or reject each test

Collection of Information in Manufacturing Shop Floor

– Recording information through touch interface on fixed or mobile devices

– Production line segmentation

– Recording of produced quantities

– Recording of production times and stops

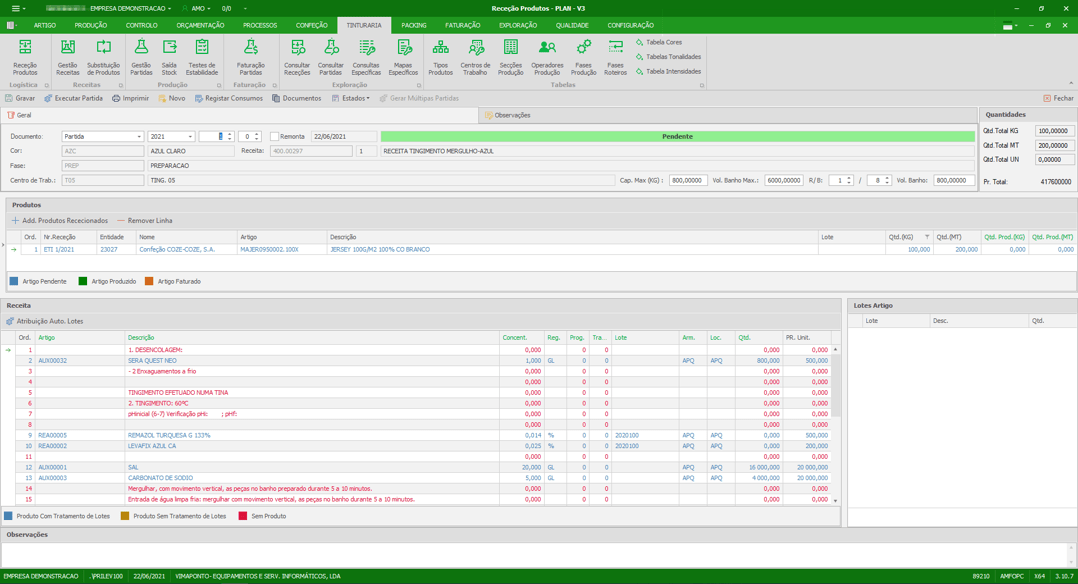

Dyeing Management

– Recipe creation and management

– Integration of recipes with “jets” of dyeing

– Receipt of materials

– Item management (one or several manufacturing orders)

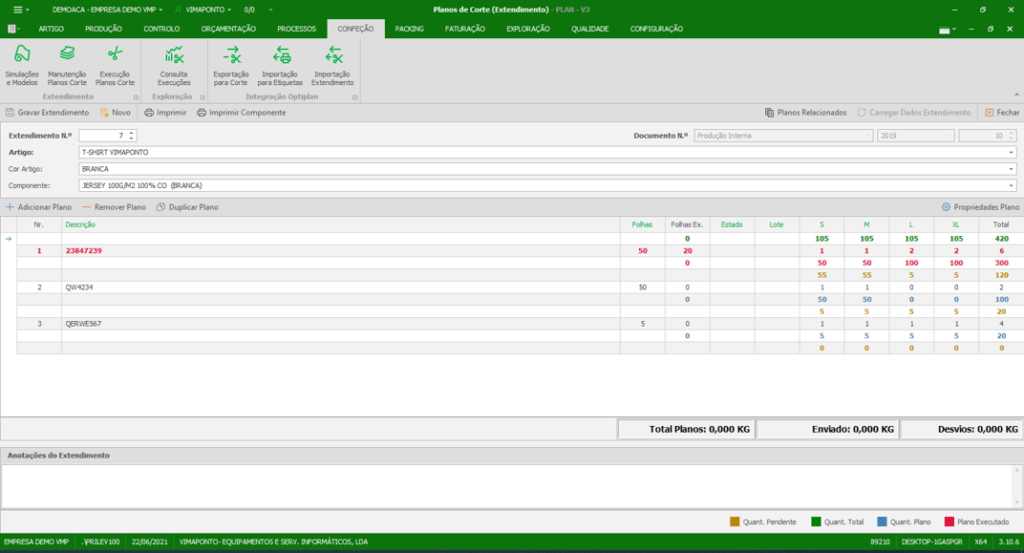

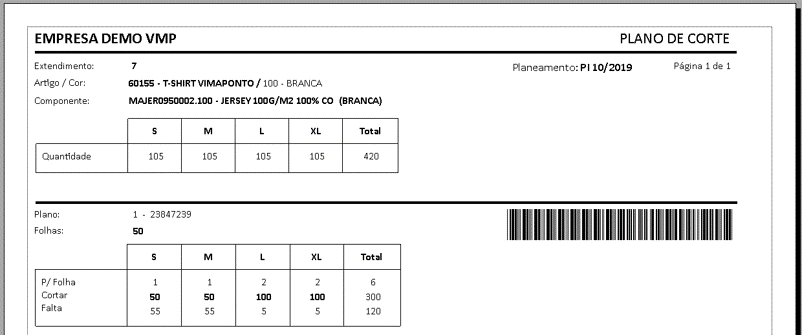

Cutting Plan Management

– Definition of extension plans for cutting

– Unlimited cutting plans per article/color/component

– Execution via barcode reading

– Integration with Optiplan, ICF, Audaces