Automate Production in the Footwear Industry with VMP Plan

Companies in the footwear sector are constantly faced with the need to optimize processes to enhance competitiveness and profitability. VMP Plan, integrated into Cegid's ERP v10, is a comprehensive vertical management solution that encompasses the entire organization, from production to top-level management.

The VMP Plan solution promotes the entire production cycle management in a fully integrated manner, eliminating the most time-consuming and low-value-added tasks. It encompasses all the production processes of footwear manufacturing, such as:

– Sample creation

– Cutting

– Pre-sewing

– Sewing

– Packaging

– Shipment of the final product

This solution is the result of more than 35 years of experience in the productive sector, having incorporated a set of standard processes combined with flexibility that allows adapting the VMP Plan to the specific needs of each organization.

main features

Budgeting

– Budget creation without creating items

– Multiple versions for the same budget

– Various budget templates

– Budget approval

– Commission definition for automatic calculation

– Attribute transfer to the article record

Product Development

– Management and control of sample execution

– No need to create an article

– Customers or potential customers

– Various execution and control workflows

– Unlimited and user-configurable operations/steps

– Cost and time recording per operation

– Automatic email notification upon operation completion

– Sample documentation repository

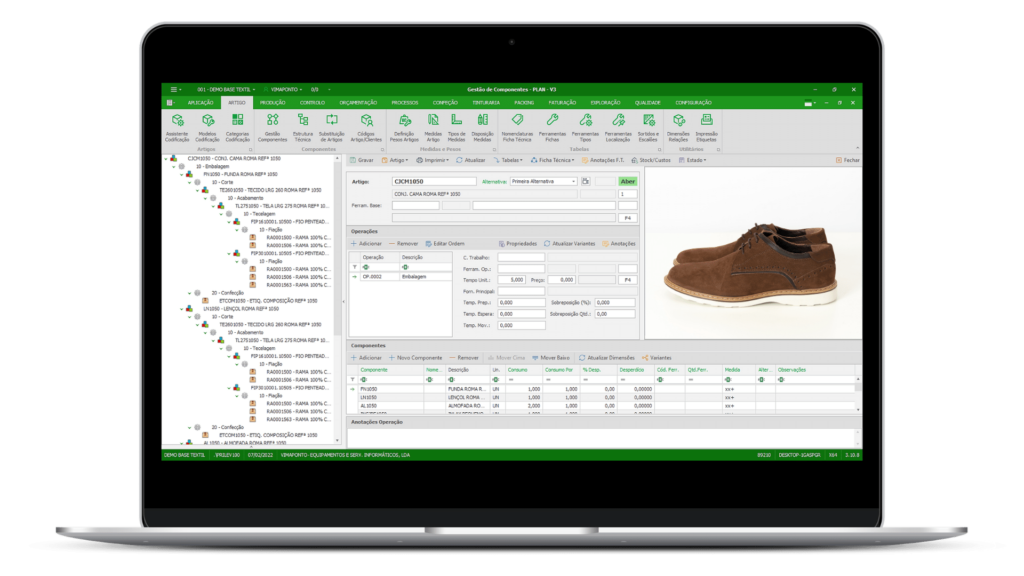

Assisted Creation of Articles / Technical Sheet

– Oriented article creation

– Automatic attribute suggestions

– Graphic exploration of article composition

– Product technical sheet without operation limits

– Automatic assignment of colors and sizes

– Technical sheet combination

Needs Calculation

– Automated supplier analysis and requisition

– Calculation with multiple parameters: current and minimum stock, supplier requisitions, operations, and warehouses

– Assisted entry

Planning

– Execution planning per operation

– Graphic planning by workstation

– Planning for in-house or subcontracted execution

– Automatic generation of service orders

– Aggregation of multiple plans into one or more supplier orders

Movement

– Permanent inventory

– Material preparation

– Automatic issuance of certified goods tracking document

– Movement executed by operators

– Visibility and recording by subcontractors

– Material return

Packing and Picking

– Automatic and/or manual distribution by packaging type, destinations, and dimensions

– Various packings per order

– Automatic label creation

– Customization of labels and packing by customer

– Packing executed in terminal

– Calculation of volume and weight

Shipment and Invoicing

– Shipment or Invoicing from the order

– Shipment or Invoicing from the Packing List

Quality Control

– Flexibility in configuring quality tests

– Segmentation by families, brands, etc.

– Definition of test collection moments

– Parameterization and customization of factors that approve or reject tests

Exploration and Analysis

– Production status analysis

– Cost analysis

– Product traceability

– Article statement and inventory by manufacturing order

– Work diary

– Business Intelligence

Collection of Information in Manufacturing Shop Floor

– Recording information through touch interface on fixed or mobile devices

– Production line segmentation

– Recording of produced quantities

– Recording of production times and stops